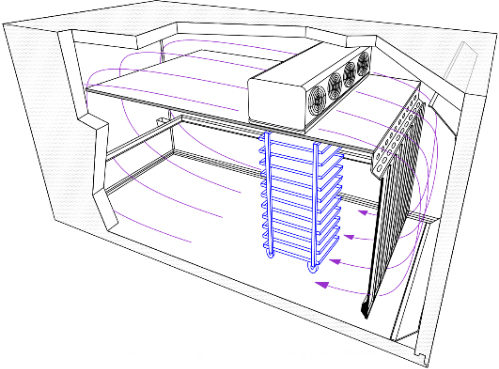

PROOFING SYSTEM WITH OR WITHOUT COUNTER-COOLING

PR

Our PROOFER with or without counter-cooling is ideal for stable and uniform proofing processes of premium baked goods. Specifically designed for bakeries, this system allows for optimal proofing of small wheat products, rolls, and bread. We guarantee stable and consistent temperature control, resulting in consistent quality of your baked goods with perfect texture and flavour development.

- Strongly insulated wall and ceiling panels

- SOFTSTEAM humidification system

- Interior LED lighting

- Optional swing or high-speed door

- Customized design

- Strongly insulated wall and ceiling panels

- SOFTSTEAM humidification system

- Interior LED lighting

- Optional swing or high-speed door

- Customized design

AIRSTREAM dough storage without drying out, with highest quality assurance

AIRSTREAM+ with variable automatic pressure walls for opening and closing the air pressure sides

PANEL SEALS

- Very fine seams

- Internal seal

- No extrusion of sealing bands

ROUNDED INSIDE CORNERS

-

Rounded corners from

-

one piece

-

No “dirt strips”

PANEL CONNECTION

-

No transverse seams on the outside

Softsteam

SoINSPIRED BY NATURE

The SOFTSTEAM evaporative humidification keeps the water just above room temperature, minimizing the temperature difference with the dough pieces. The evaporation tank is gently heated, resulting in natural evaporation over a large surface area. This technology preserves baked goods and is highly energy-efficient. The balanced moisture balance ensures optimal dough quality, with no moisture deposits or puddles. The SOFTSTEAM humidification system is also maintenance-free.

LONG-TERM CONTROL THROUGH A CONTROLLED FERMENTATION PROCESS WITH SOFTSTEAM, ONLY FROM ICECOOL.

Intra Cart

INTRA CART links qualitative processes technically to achieve the most economically optimal outcome.

Our automatic baking rack transport system is robust, highly reliable, and specially designed for fermentation or shock cooling processes. The stainless steel drive system and the PLC control with touch screen offer the highest performance and flexibility. HACCP compliance is ensured through splash protection and an automatic cleaning and drying program, guaranteeing the highest hygiene standards with INTRA CART.

Errors due to inadequate fermentation or shock cooling are a thing of the past. With minimal personnel, you can safely handle this sensitive area of work while deploying your workforce profitably in other areas of production.

iSpeed

With ISPEED, you can operate your cold rooms and proofing chambers partially or fully automatically, maintaining the ideal environment for your valuable baked goods.

ICECOOL ISPEED high-speed doors are specially designed for areas with high foot traffic. They allow for quick sealing of the room climate, minimizing heat loss when opened. Thanks to these automatic doors, you can efficiently load and unload your ICECOOL equipment while saving valuable space resources.

ISPEED high-speed doors are HACCP-compliant and ensure the highest quality and hygiene in your production. With high-quality technology and precise control, you can optimize your workflow and maintain the quality of your baked goods.

ICS-Touch

THE 12 INCH TOUCHSCREEN CONTROL

ADVANTAGES OF ICECOOL ICOM CONTROL

-

Intuitive operation through touch screen control on site or remotely via smartphone, tablet and PC.

-

Flexible programming of the 7 phases per daily cycle for FULLPROOFING and SLOWPROOFING systems.

-

Tailored programs for different baked goods.

-

Networking of all refrigeration systems for seamless control.

-

HACCP temperature recording and documentation for high hygiene standards.

-

Efficient monitoring and organization of workflows and data recording.

-

Quick notification of malfunctions by email.

-

Remote access for support and analysis

WHAT EXPERTS SAY

WHThe combination of high-tech, combined with traditional craftsmanship, is fascinating to me.

The SOFTSTEAM humidification system resembles a natural phenomenon: gentle natural mist settling on a sunny autumn morning over the lake. The ISAVE energy concept was another crucial point – high energy savings and thus a reduction in carbon emissions.

SLOWPROOFING – FLAVOR THAT COMES FROM THE COLD. A DECISION I WOULD NEVER CHANGE

Based on traditional dough handling methods, the new refrigeration technology was to be precisely controlled, especially for processes in the positive temperature range. Soetebier produces today at the most cutting-edge and energy-efficient level, while combining it with their in-house craftsmanship.

Bread and cakes made from traditional master recipes – with long dough preparation for long-lasting satisfaction.

The coveted sliced rolls are delivered to sales locations throughout Düsseldorf after a long period of storage and maturation in a total of 10 ICECOOL refrigeration units. This ensures that OEHME customers always enjoy fresh rolls – crispy, crusty, and aromatic with a beautiful sheen!

The 260-year-old family business grows its own grain for the Bioland-certified products.

Rot am See, Germany

Preserving Tradition and Progress with ICECOOL

Preserving and advancing the craft and modern culinary culture are paramount. Elaborate recipes are executed using natural ingredients from the region.

Tender, delicious sliced rolls with a glossy finish and a lot of flavour – baked goods for the Champions League.

Exactly what Jürgen Hinkelmann had envisioned: No more pushing around of racks, no more sources of error in the rapid cooling processes. A secure cooling process where evenly baked and ready-to-bake dough pieces are delivered to over 50 branches.

Mastering the Art of Sliced Rolls – Cooling and Conditioning with Plastic Boards

In 1959, Hans and Brigitta Bolten founded the renowned company, which is now being run by the Bolten family in its second generation, with over 40 branches. An air-conditioned bread roll production facility is the centrepiece of the business expansion.